Metal Deactivators

Metals can accelerate thermal oxidation of polyolefins and related plastics such as EPDM. To prevent metal catalyzed degradation, it is often neccessary to combine an antioxidant with a metal deactivator if the former does not already contain a moity with radical scavenging properties.

The function of a metal deactivator or metal deactivating agent (MDA) is to form an inactive complex with the catalytically active metal ion. Thus, complexation of the metal with the chelating agent prevents metals from associating with hydro-peroxides, i.e., it decreases its ability to produce radicals from hydroperoxides by oxidation or reduction.

Most chelating agents are well suited for this purpose because they form thermally stable metal complexes. The general feature of chelating agents is their polyfunctionality. They contain several ligand atoms such as N, O, S, P often in combination with functional groups such as hydroxyl, carboxyl, carbonyl, or carbamide.

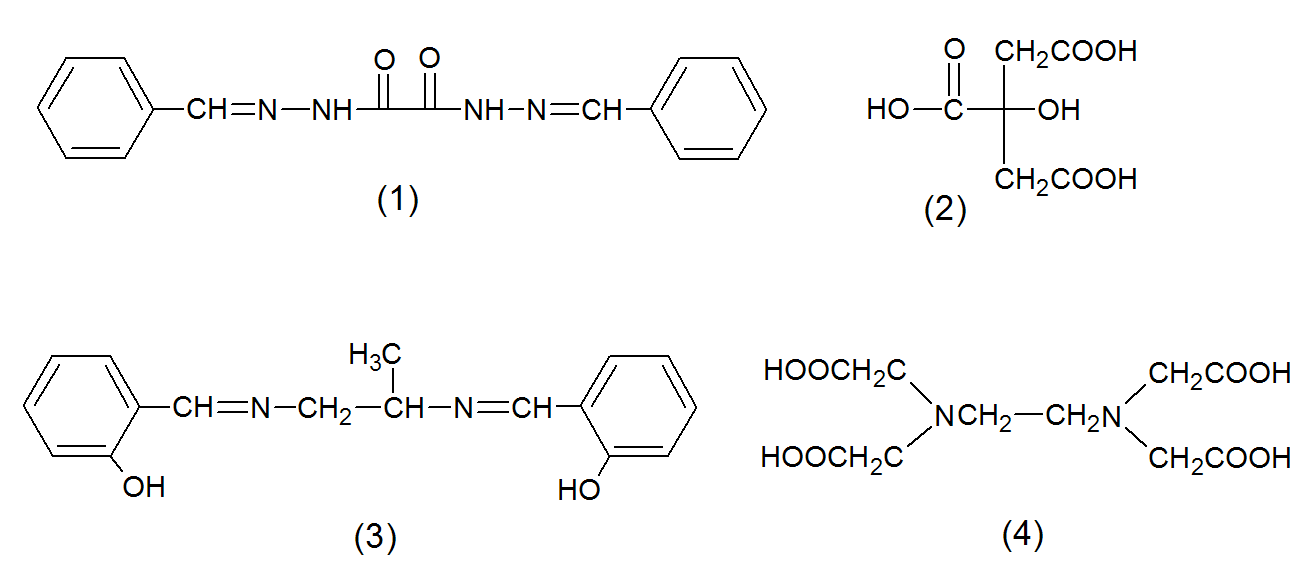

Common metal deactivators include oxyalyl bis(benzylidene)hydrazine (1), citric acid (2), N,N'-(disalicylidene)-1,2-propanediamine (3), ethylene-diaminetetraacetic acid (EDTA) and its salts (4), mercaptobenzothiazoles, mercaptobenzimidazoles and many thiadiazole and triazole derivatives to name only a few.

The different substituents will affect the properties, like polarity, volatility, miscibility, and UV absortion spectrum.